Melt Non-Woven Spinneret - China Manufacturers, Suppliers, Factory

All we do is usually affiliated with our tenet " Buyer to start with, Belief to start with, devoting about the food packaging and environmental defense for Melt Non-Woven Spinneret, Silk-Spinning Spinneret, Spinneret Meaning In Tamil, Non Woven Fabric Black,Pp Melt Blown Filter Cartridge Making Machine. Our products are regularly supplied to many Groups and lots of Factories. Meanwhile, our products are sold to the USA, Italy, Singapore, Malaysia, Russia, Poland, and the Middle East. The product will supply to all over the world, such as Europe, America, Australia,Belarus, Plymouth,New Delhi, Hanover.We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. Now we have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our solutions have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We're making great efforts to achieve this win-win situation and sincerely welcome you to join us.

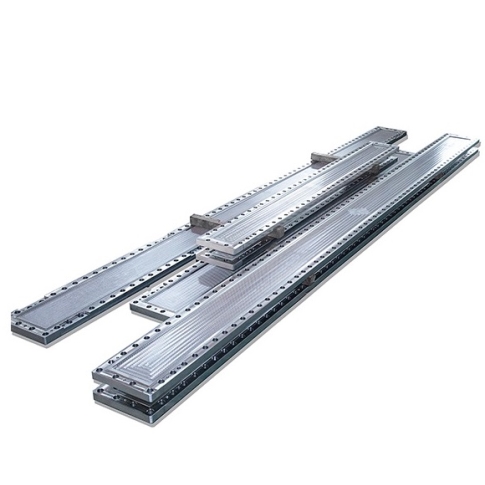

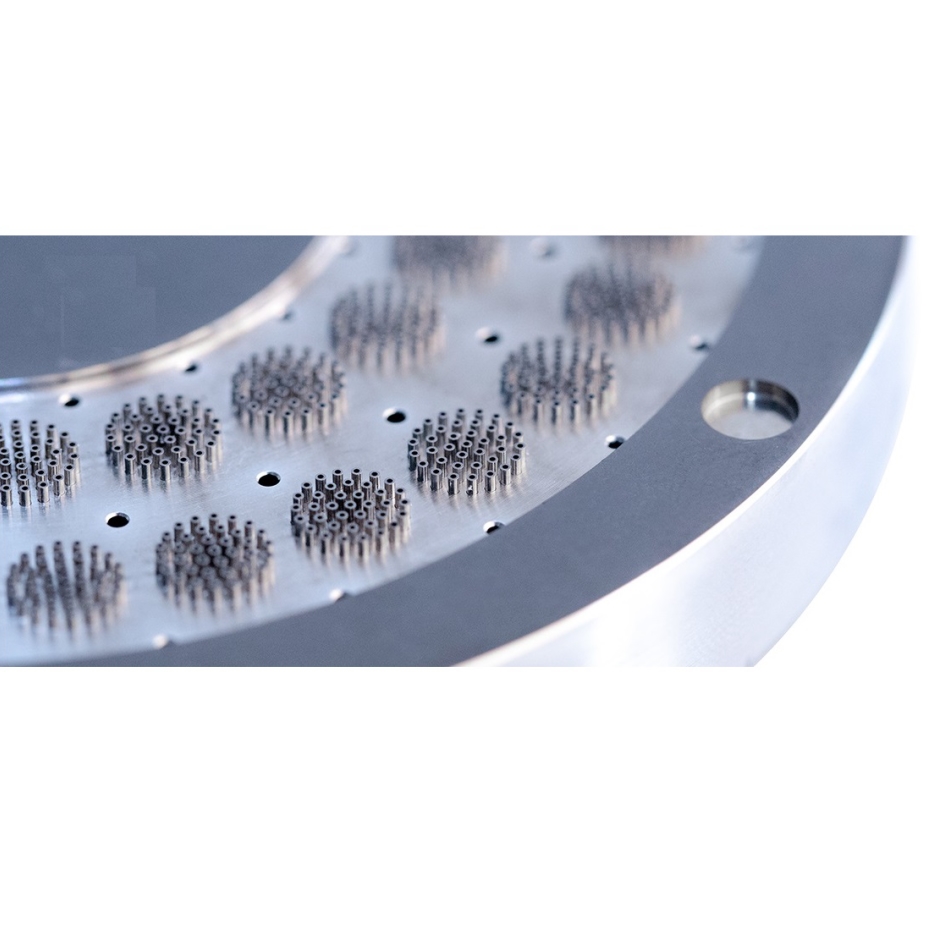

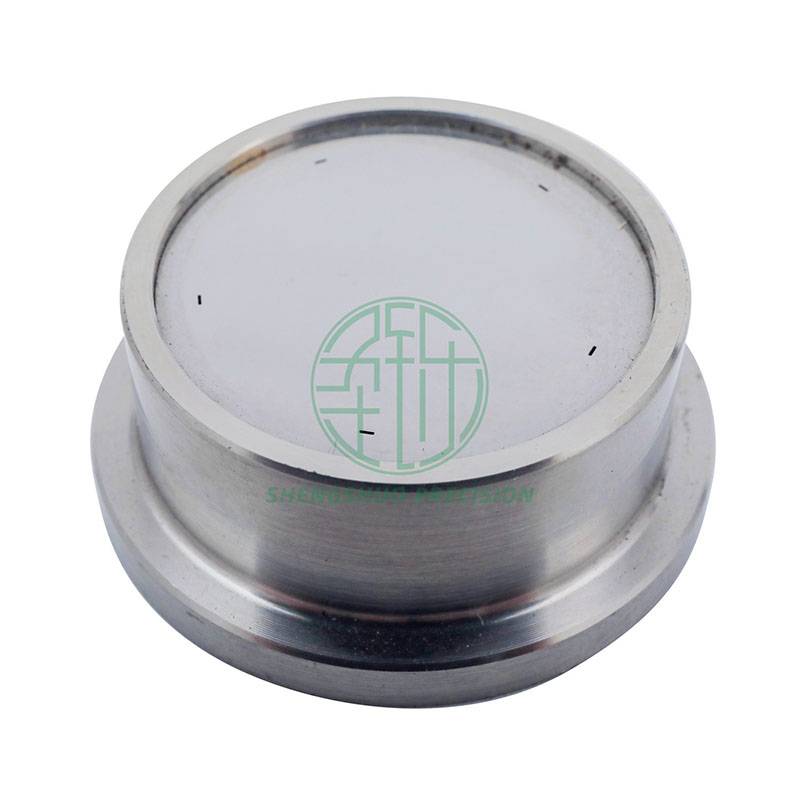

Related Products