Melt Spinning - China Factory, Suppliers, Manufacturers

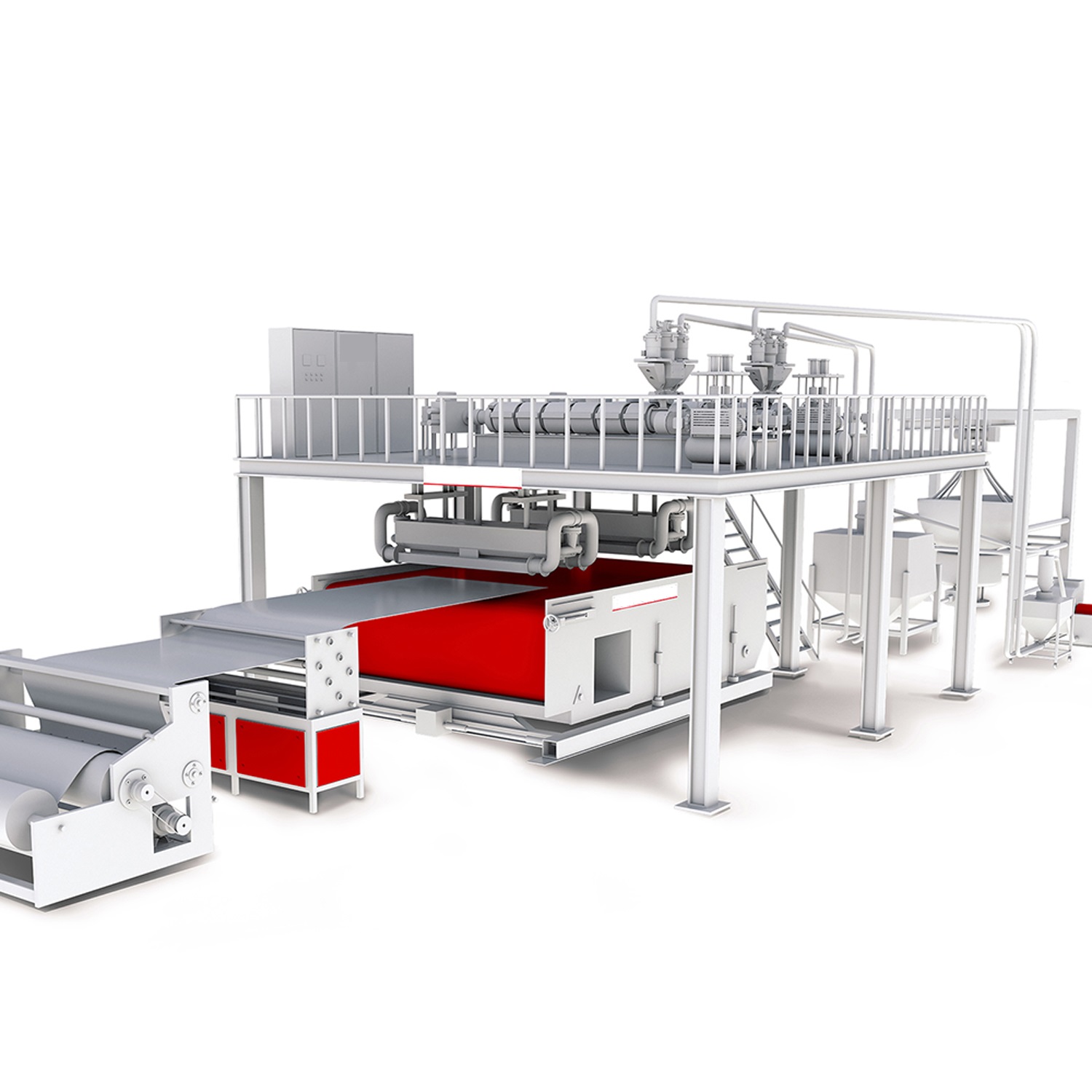

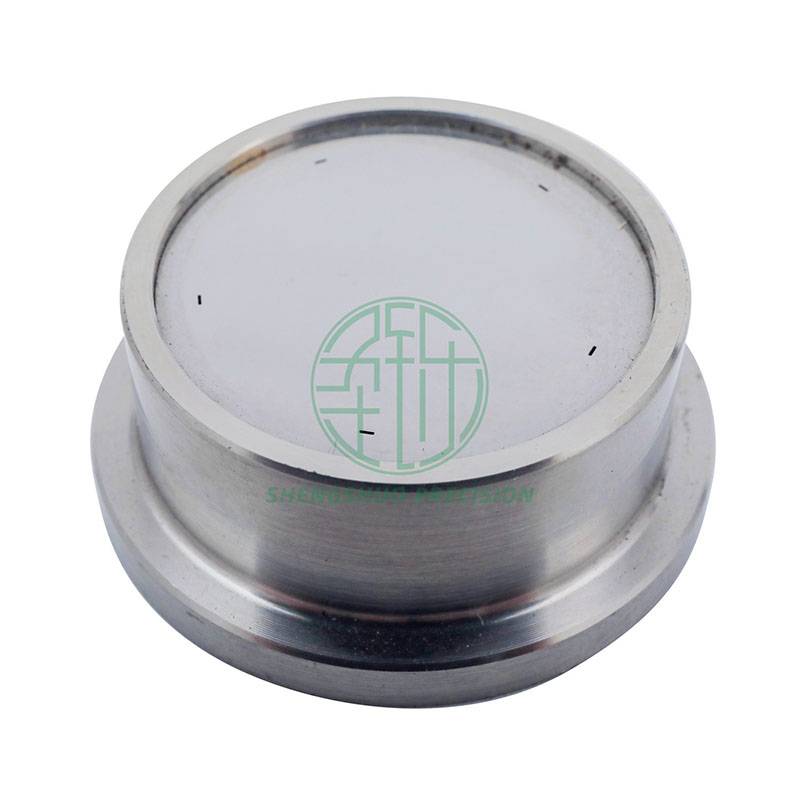

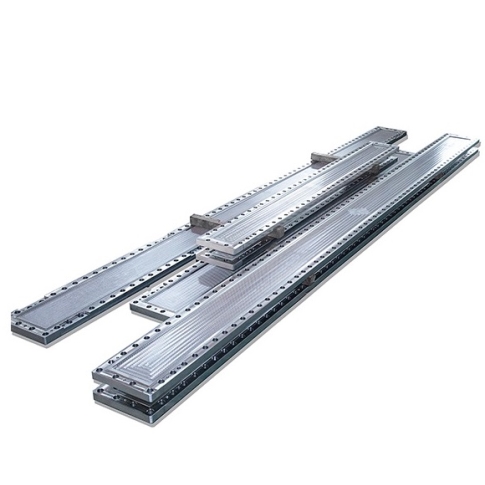

Our enterprise since its inception, often regards solution excellent as enterprise life, continually strengthen output technology, enhance product high quality and continually strengthen organization total high-quality administration, in strict accordance using the national standard ISO 9001:2000 for Melt Spinning, Caterpillar Spinneret , The Spinnerets , Melt Blown ,Metal Spinning Spinneret Parts . Your inquiry will be highly welcomed and a win-win prosperous development are what we are expecting. The product will supply to all over the world, such as Europe, America, Australia,New Zealand, Algeria,Philippines, Irish.We adhere to the honest, efficient, practical win-win running mission and people-oriented business philosophy. Excellent quality, reasonable price and customer satisfaction are always pursued! If you are interested in our items, just try to contact us for more details!

Related Products