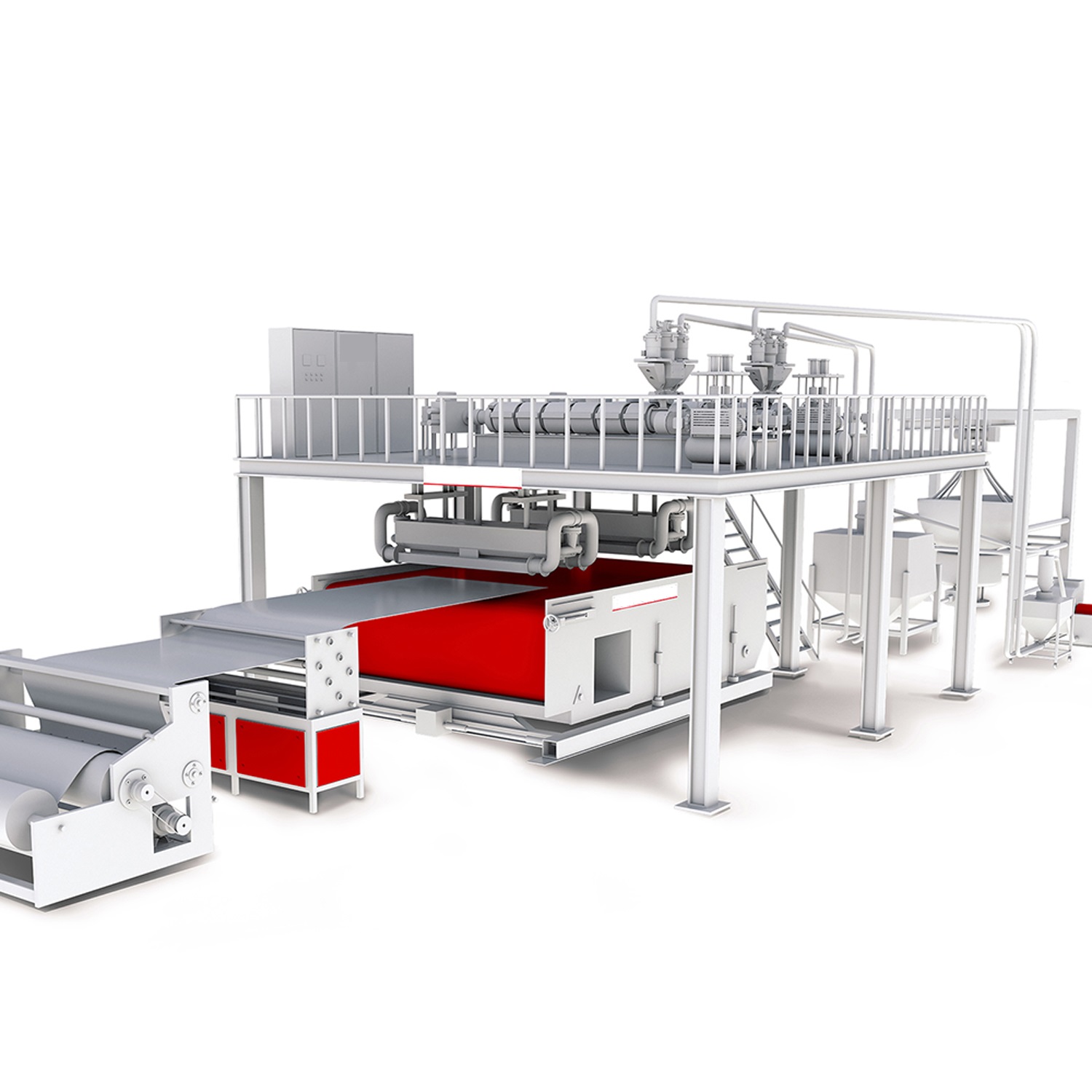

Meltblown Machine - Manufacturers, Suppliers, Factory from China

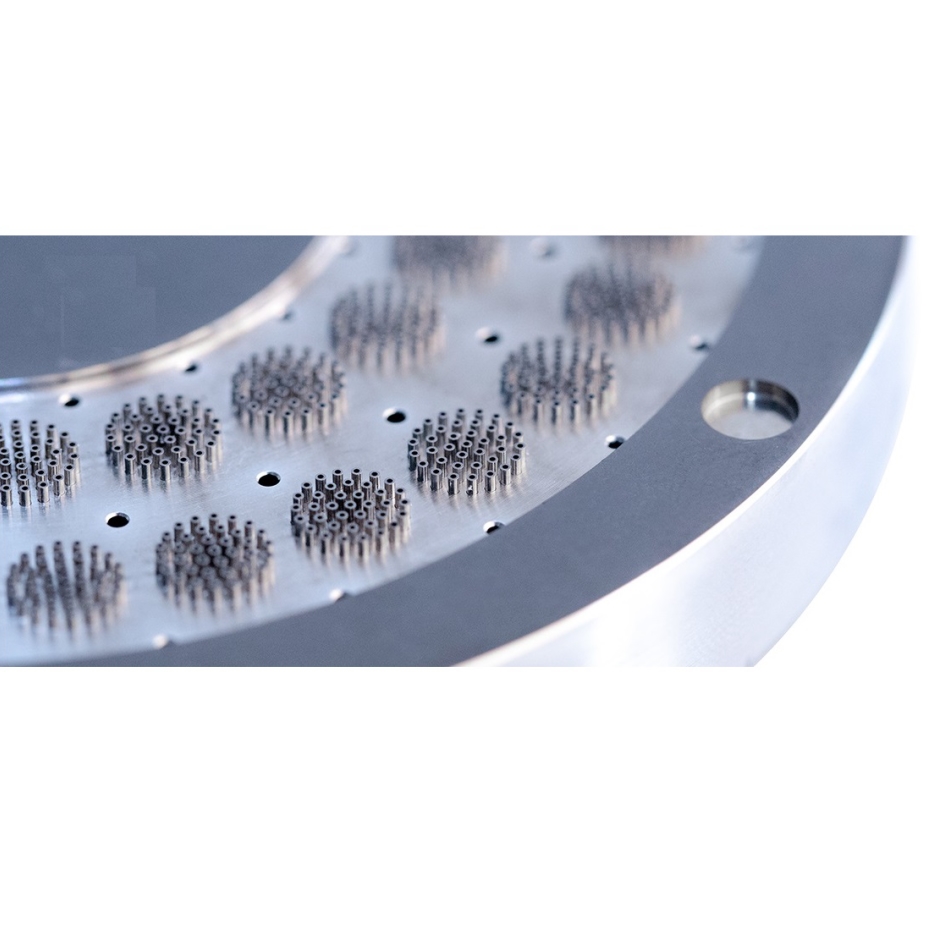

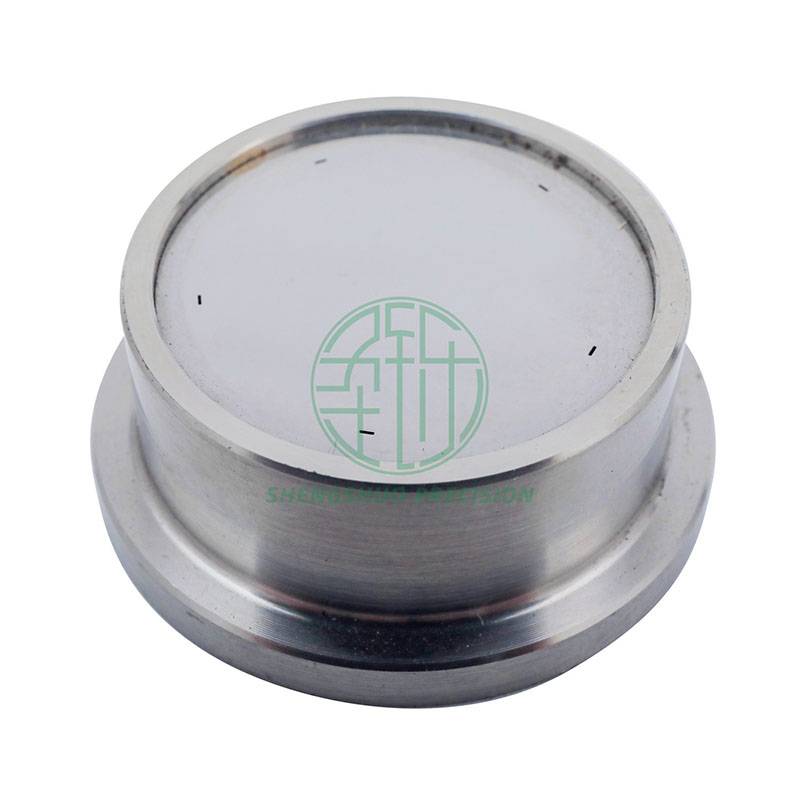

Bear Customer initially, High quality first in mind, we do the job closely with our customers and supply them with efficient and skilled providers for Meltblown Machine, Melt Spinning Extrusion , Chemical Fiber Spinneret , Melt Blown Cloth Making Machine ,Trilobal Spinneret . Making the Products of High Quality is the eternal goal of our company. We make unremitting efforts to realize the goal of We Will Always Keep in Pace with the Time. The product will supply to all over the world, such as Europe, America, Australia,Macedonia, Kenya,South Africa, Guatemala.We have our own registered brand and our company is developing rapidly owing to high quality products, competitive price and excellent service. We sincerely hope to establish business relations with more friends from home and abroad in the near future. We look forward to your correspondence.

Related Products