Epidemic - Factory, Suppliers, Manufacturers from China

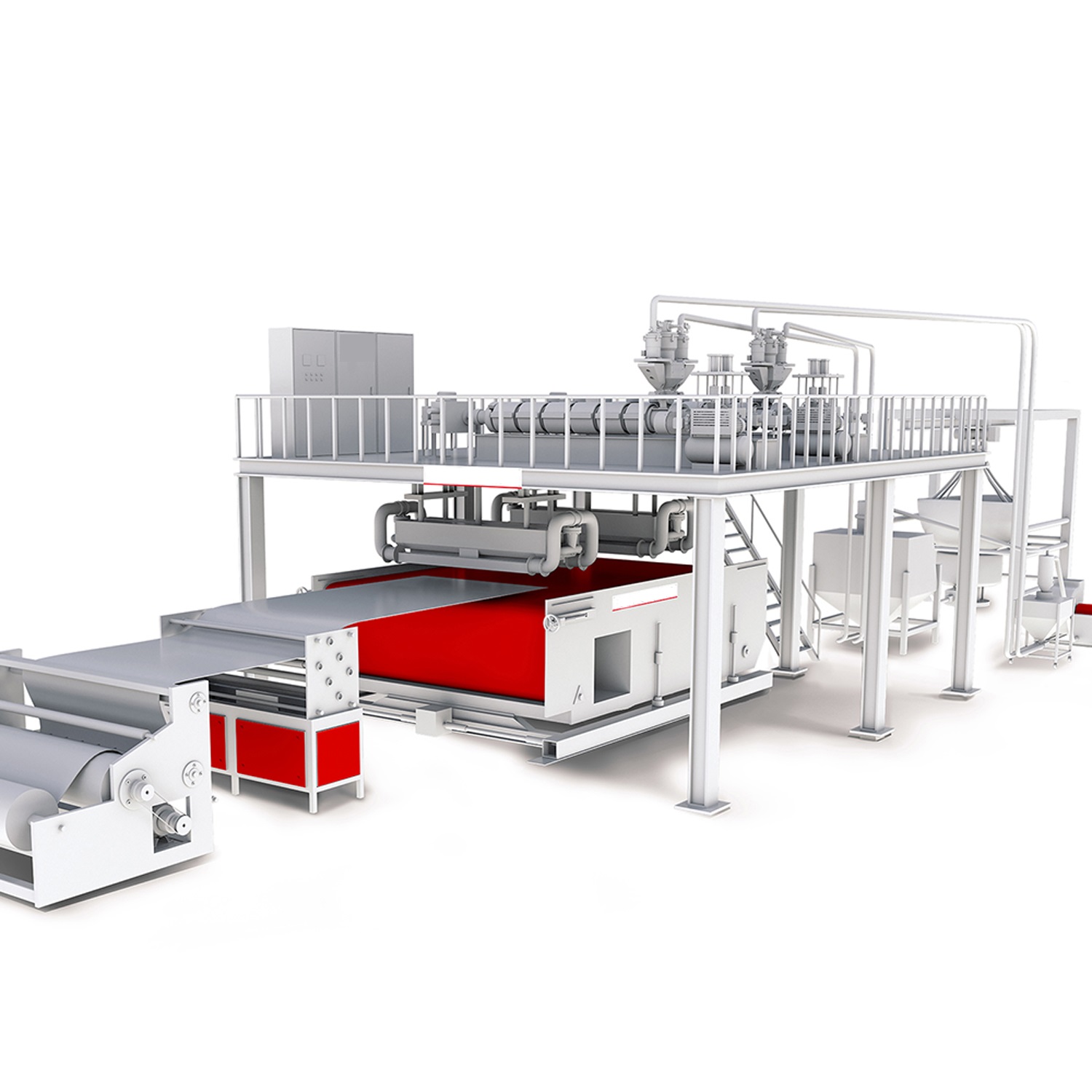

Being supported by an advanced and specialist IT team, we could give technical support on pre-sales & after-sales services for Epidemic, Melt Blown Fiber , Medical Mask, Pp Melt Blown Fabric Machine ,Sea-Island . Our company is dedicated to providing customers with high and stable quality products at competitive price, making every customer satisfied with our products and services. The product will supply to all over the world, such as Europe, America, Australia,Denmark, Eindhoven,Bulgaria, New Zealand.Our faith is to be honest first, so we just supply high quality products to our customers. Really hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products ! You will be Unique with our hair products !!

Related Products