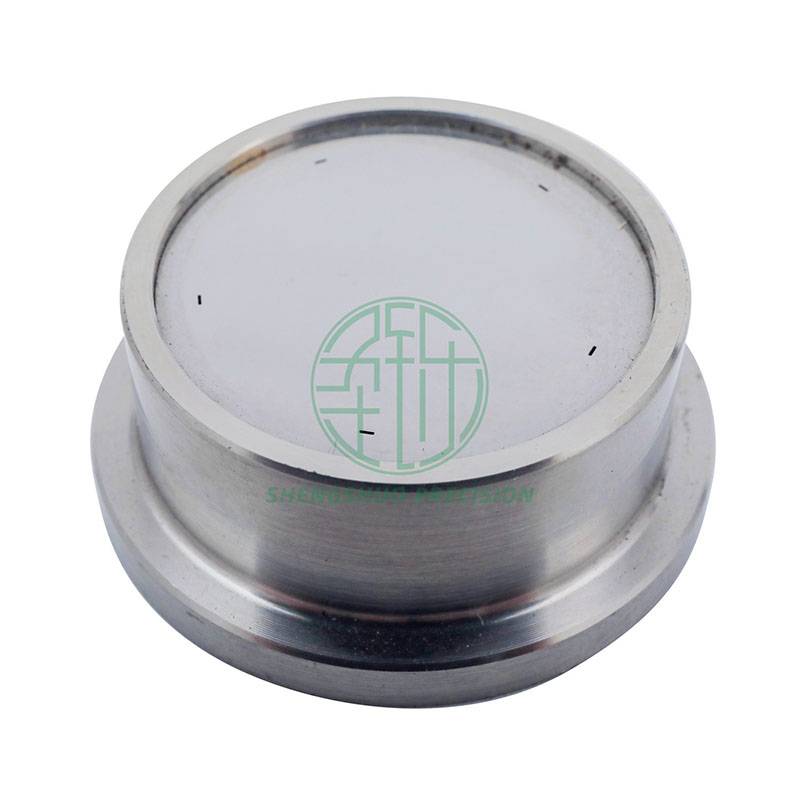

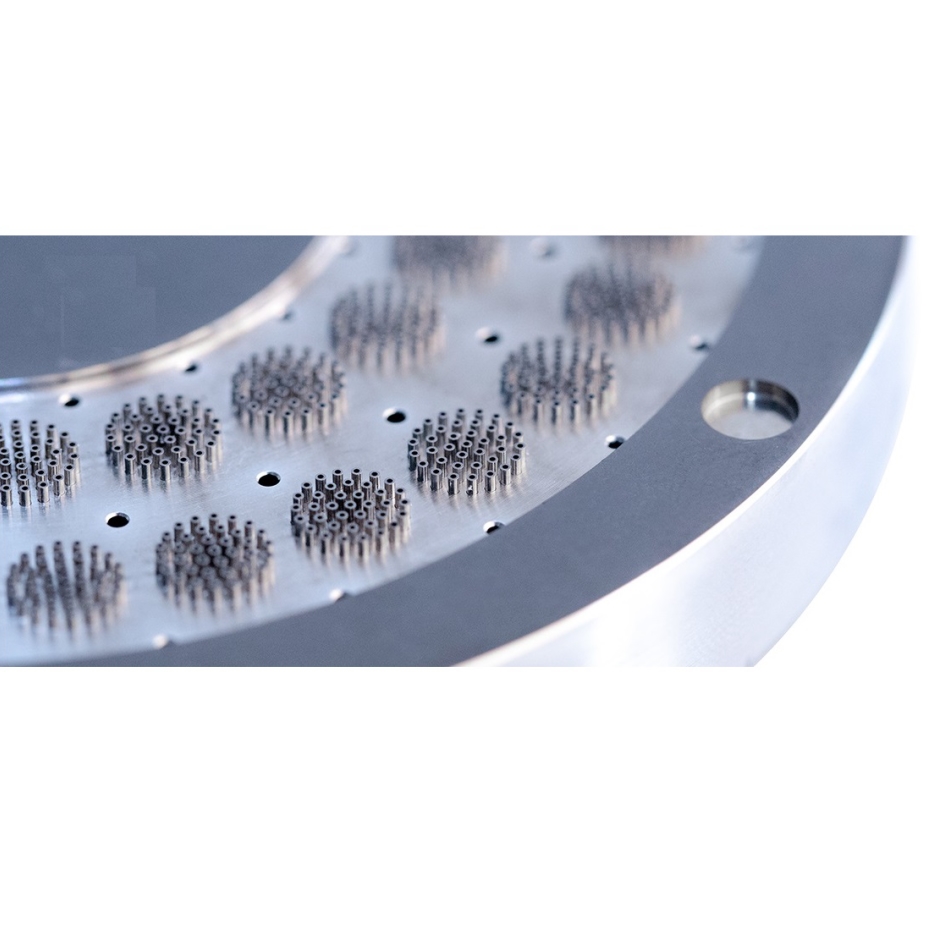

High Strength Stainless Steel Spinneret - China Factory, Suppliers, Manufacturers

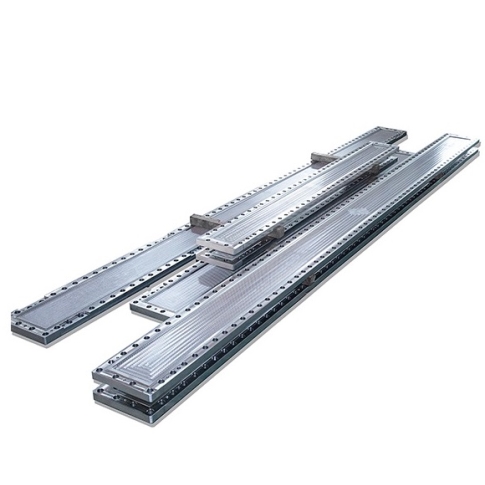

With our superb management, potent technical capability and strict quality command procedure, we go on to provide our shoppers with trustworthy high-quality, reasonable costs and outstanding services. We goal at becoming considered one of your most trustworthy partners and earning your pleasure for High Strength Stainless Steel Spinneret, Melt Spinning Extrusion, China Meltblown Machine, Non Woven Fabric Making,Melt Blown Nonwoven Fabric Making Machine. Objects won certifications together with the regional and international primary authorities. For far a lot more detailed information, make sure you make contact with us! The product will supply to all over the world, such as Europe, America, Australia,Bolivia, Sacramento,Cologne, Algeria.Our advanced equipment, excellent quality management, research and development ability make our price down. The price we offering may not be the lowest, but we guarantee it is absolutely competitive! Welcome to contact us immediately for future business relationship and mutual success!

Related Products