Melt Blown Material Machine - China Factory, Suppliers, Manufacturers

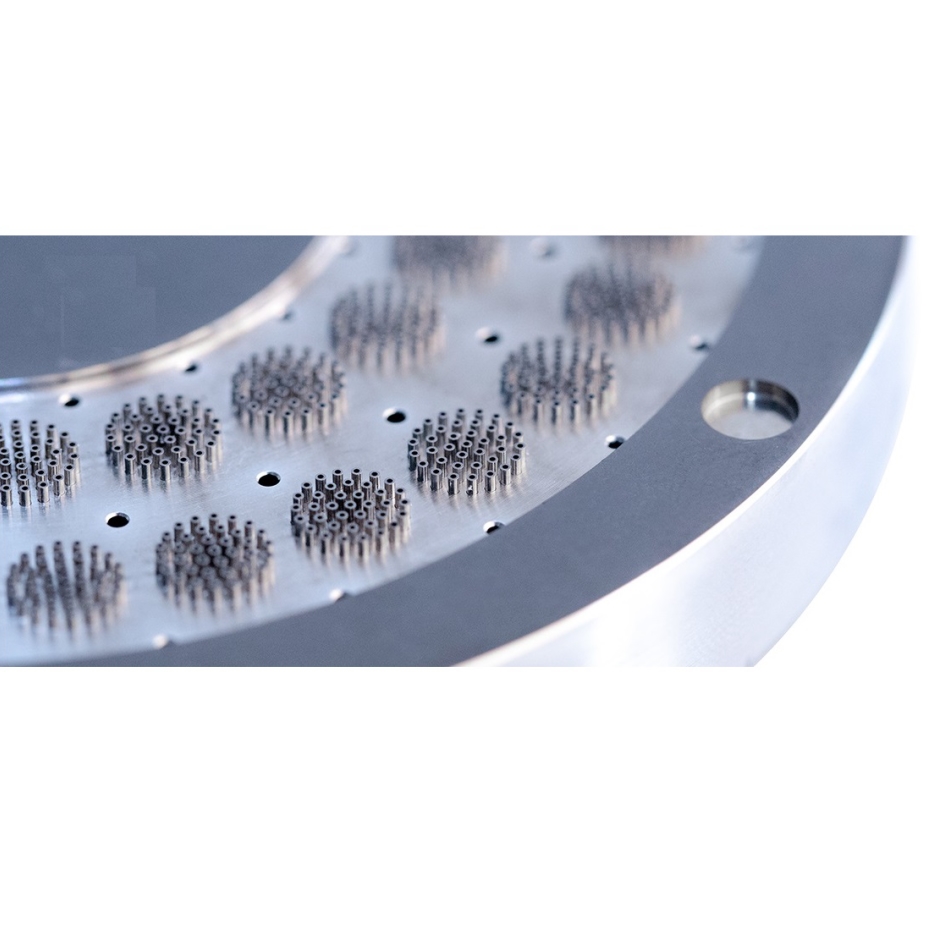

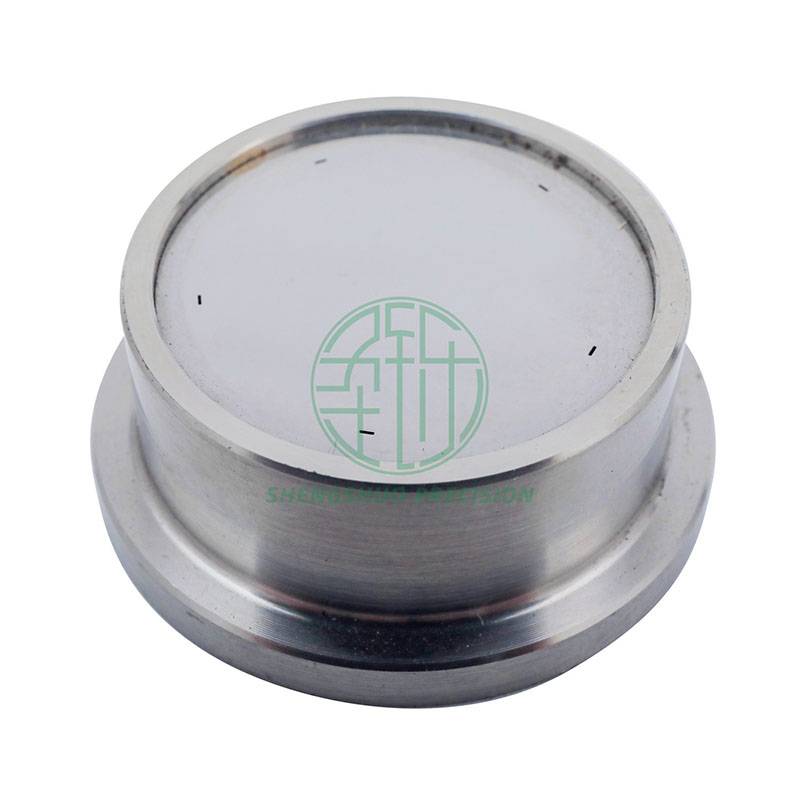

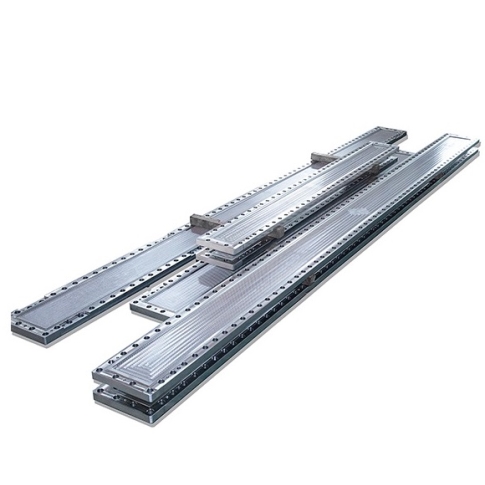

Our items are commonly identified and trusted by customers and may fulfill continuously switching economic and social wants of Melt Blown Material Machine, Melt Blown Fabric Machine Hs Code , Stainless Steel Spinneret , Non-Woven Fabric Equipment ,Textile Machinery Parts Long Life . We hope we can have a friendly relationship with businessman from all over the world. The product will supply to all over the world, such as Europe, America, Australia,Iran, Haiti,Zambia, Toronto.Good quality and reasonable price are our business principles. If you are interested in our products or have any questions, please feel free to contact us. We hope to establish cooperative relationships with you in the near future.

Related Products